Today, I will guide you through the essential steps to creating barcode labels, a key element in streamlining your inventory management. By implementing barcoding essentials, you’ll be able to drastically improve your inventory accuracy, save time, and reduce errors in your operations. With my expert guidance, you will learn the fundamental principles of barcode label creation, enabling you to take control of your inventory and transform the way you manage your business. Let’s dive in and take the first step toward a more efficient and effective inventory management system.

Key Takeaways:

- Efficiency: Creating barcode labels helps streamline inventory management by speeding up the process of tracking products and assets.

- Accuracy: Barcoding ensures accurate inventory counts and reduces the risk of human error in data entry.

- Cost-Effectiveness: Implementing barcoding can lead to cost savings by improving inventory accuracy and reducing labor hours spent on manual tracking.

- Integration: Barcode labels can be easily integrated with inventory management systems to provide real-time tracking and reporting.

- Scalability: Barcoding allows for easy scalability as businesses grow, making it an essential tool for efficient inventory management.

Understanding Barcoding Essentials

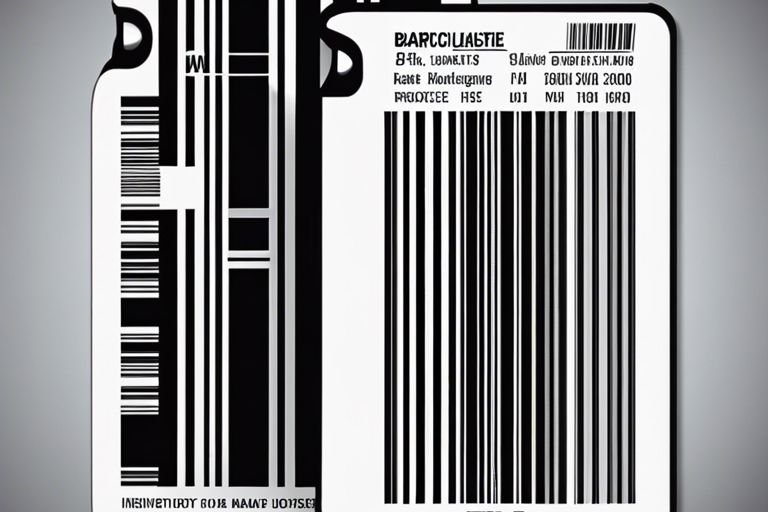

To effectively streamline inventory management with barcode labels, it’s essential to understand the basics of barcoding. Barcoding is the process of assigning a unique code – typically a series of black and white lines – to each item in inventory for the purpose of tracking and managing it efficiently. This unique code enables quick and accurate data capture using a barcode scanner, greatly improving the speed and accuracy of inventory management processes.

How to Choose the Right Barcode Label

When it comes to choosing the right barcode label for your inventory, it’s important to consider your specific needs and requirements. Factors such as the type of surface the label will be applied to, environmental conditions, and the size and type of barcode required, must all be taken into account. In order to ensure that your barcode labels are durable and scannable, it’s essential to choose the right material, adhesive, and barcode symbology.

Tips for Creating Effective Barcode Labels

When creating barcode labels, there are a few key tips to keep in mind to ensure their effectiveness. Firstly, it’s important to ensure that the label is of high quality, with clear printing and durable material. Secondly, consider the size of the label and the barcode, ensuring that it is easily scannable. Additionally, including relevant information such as the item name, SKU number, and expiration date can make the barcode label more informative and useful. Lastly, consider adding a human-readable interpretation of the barcode to facilitate manual checks and verification of the data. Perceiving these key elements will help create effective and reliable barcode labels for your inventory.

- High quality and durable material

- Optimal size for scannability

- Including relevant information

- Human-readable interpretation

Implementing Barcoding for Inventory Management

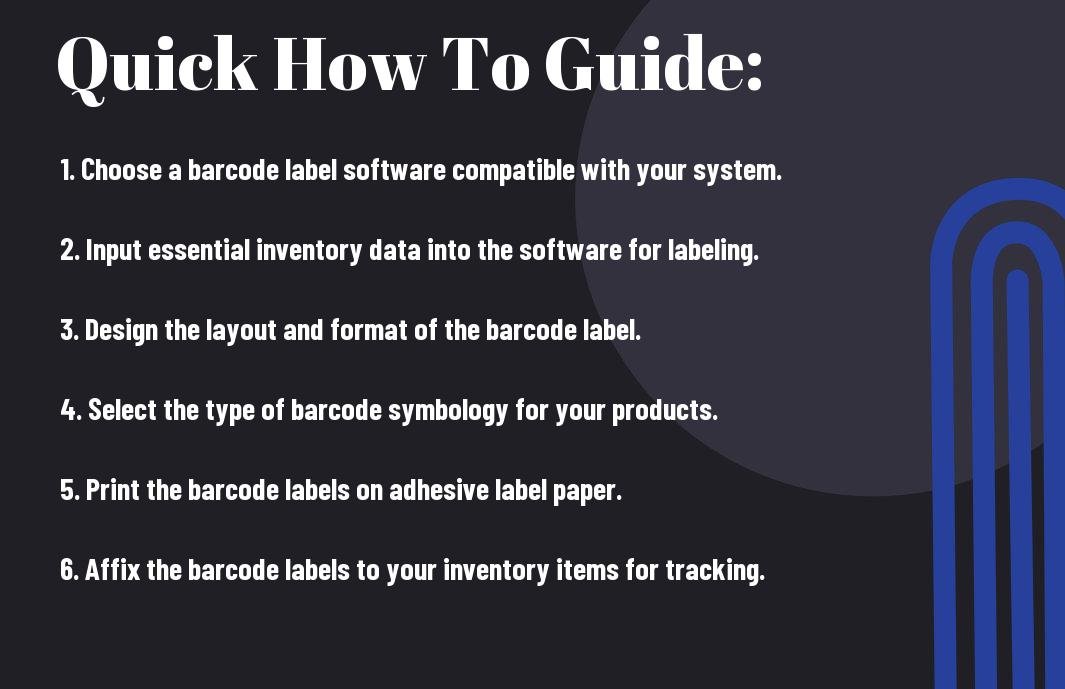

Assuming you have made the decision to implement a barcoding system for your inventory management, it is essential to carefully plan and execute the process to ensure its successful integration into your operations. Barcoding can significantly improve efficiency, accuracy, and visibility of your inventory, but it requires meticulous planning and execution to achieve the desired results. In this chapter, I will guide you through the essential steps to effectively implement barcoding for inventory management.

Factors to Consider When Implementing Barcoding System

When implementing a barcoding system for inventory management, there are several factors to consider to ensure a smooth and successful transition. First and foremost, you must assess the specific needs and requirements of your business. Consider the size of your inventory, the nature of your products, and the volume of transactions. It is also crucial to evaluate your current infrastructure, including the capabilities of your existing software and hardware. Additionally, training your staff and ensuring their buy-in is essential for the successful adoption of the barcode system. Your budget for implementing the system and ongoing maintenance should also be carefully considered. Lastly, it is important to establish a clear timeline for the implementation process to avoid disruptions to your daily operations.

- Business needs and requirements

- Assessment of current infrastructure

- Staff training and buy-in

- Budget and ongoing maintenance

- Establishing a clear timeline

Recognizing the significance of these factors and addressing them proactively will greatly contribute to the successful implementation of a barcoding system for your inventory management.

How to Streamline Inventory Management with Barcoding

Once the barcoding system is in place, you can leverage its capabilities to streamline your inventory management processes. By scanning barcodes, you can easily track the movement of items in and out of your inventory, effectively reducing the margin of error and enhancing the accuracy of your records. The real-time visibility provided by barcoding allows you to make informed decisions regarding inventory levels, reordering, and stock allocation. Furthermore, integration of barcode data with your existing inventory management software can lead to improved efficiency and better decision-making. With accurate and up-to-date information at your fingertips, you can optimize your inventory management practices and ultimately improve the overall performance of your business.

Ensuring Accuracy and Efficiency

Now that you have implemented barcode labels in your inventory management system, it is crucial to ensure accuracy and efficiency in the processes. Barcoding can significantly improve the speed and precision of your inventory management, but it requires attention to detail and proper maintenance to maximize its benefits. In this chapter, I will provide insights into how you can optimize the use of barcode labels to achieve accuracy and efficiency in your inventory management.

Tips for Scanning and Reading Barcode Labels

When it comes to scanning and reading barcode labels, there are certain best practices that can help you achieve maximum efficiency and accuracy:

- Ensure proper lighting and angle for scanning barcode labels

- Regularly clean and maintain barcode scanners for optimal performance

- Conduct regular training for staff on proper scanning techniques

Knowing these tips can significantly improve the speed and accuracy of barcode scanning, ultimately enhancing your overall inventory management processes.

Factors for Maintaining Barcode Label Quality

Maintaining the quality of your barcode labels is essential for ensuring accuracy and efficiency in your inventory management. Factors to consider when maintaining barcode label quality include:

- Using high-quality barcode label printing materials

- Regularly inspecting and replacing damaged or worn-out barcode labels

- Ensuring proper placement and adherence of barcode labels on inventory items

After all, the quality of the barcode labels directly impacts the accuracy and efficiency of your inventory management processes.

Conclusion

Now, you have mastered the essentials of creating barcode labels and streamlining your inventory management system. By incorporating barcode technology into your business operations, you will be able to improve accuracy, efficiency, and productivity. Your organization will benefit from reduced human error, increased speed of operations, and better control of stock levels. With the information in this guide, you have the tools to take full advantage of barcoding essentials and optimize your inventory management processes. So, go ahead and start implementing barcodes in your business today and enjoy the benefits of a more organized and efficient system.

FAQ

Q: What is a barcode label and how does it streamline inventory management?

A: A barcode label is a unique code represented by a pattern of parallel lines of varying widths. It streamlines inventory management by allowing quick and accurate identification of items, reducing human error and improving efficiency in tracking inventory levels and movement.

Q: What essential components are needed to create a barcode label?

A: To create a barcode label, you will need a barcode scanner, label printer, barcode software, and a database to store the barcode information. The barcode scanner reads the barcode, the label printer prints the barcode label, and the software and database are used to design, store, and manage the barcode data.

Q: How can I choose the right barcode type for my inventory?

A: The most common barcode types are UPC, EAN, Code 39, and Code 128. The right barcode type for your inventory depends on the type of products, industry standards, and the level of information you need to encode. Consult with a barcode expert to determine the best barcode type for your specific inventory needs.

Q: What are the benefits of using barcode labels for inventory management?

A: Using barcode labels for inventory management provides benefits such as improved accuracy, reduced labor costs, faster inventory counts, enhanced traceability, and streamlined operations. It also enables real-time visibility into inventory levels and reduces the risk of stockouts or overstock situations.

Q: How can I implement barcode labels in my inventory management system?

A: To implement barcode labels in your inventory management system, start by evaluating your current processes and identifying where barcoding can bring the most value. Then, invest in the necessary hardware and software, train your team on how to use the barcode system, and gradually transition to using barcode labels for all inventory-related tasks. Continuous monitoring and adjustments are essential for successful implementation.